SURVEILLANCE SYSTEM

IN BUILT DUAL CAMERA SYSTEM FOR MONITORING BOTH THE DUAL TABLES

FRACTIONAL AUTOMATIC ROLLERS SUPPORT

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

The fifth-generation aviation aluminum alloy beam

Ultra-high-pressure stretching process and lightweight design. The whole beam is processed by T6 heat treatment process to make the beam obtain the highest strength Rigidity increases by 60% ; Weight goes down by 20% ; Laser cutter running speed increases by 50%

Active Anti-collision Function

Fiber laser heads are able to detect cutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

HIGH SPEED DISTANCE SENSOR

MAINTAIN A FIXED CUTTING HEIGHT DURING a high speed cutting thanks to its high speed distance sensor which automatically turn on Vibration Suprpression when sheet start to Vibrate

HIGH SPEED FOCUS SHIFT

The auto-focusing optical fiber cutting head has a built-in motor drive unit. The focus lens is driven by a linear mechanism to automatically change the position within the specified range. The continuous focus can be set by the program to complete the rapid perforation of thick plates and automatically cut plates of different thicknesses and materials.

SUPER HEAVY PLATE WELDING MACHINE BED

The bed adopts super-thick monolithic steel plate laser blanking.The groove welding method is used to make the plates reach equal strength butt Then it undergoes stress annealing and natural aging treatment to eliminate internal stress and maintain the extremely high stability and cutting accuracy of the bed.Each frame of the cutting machine bed is welded after mortise-and-tenon joint to achieve perfect mechanical property and better stability and firmness

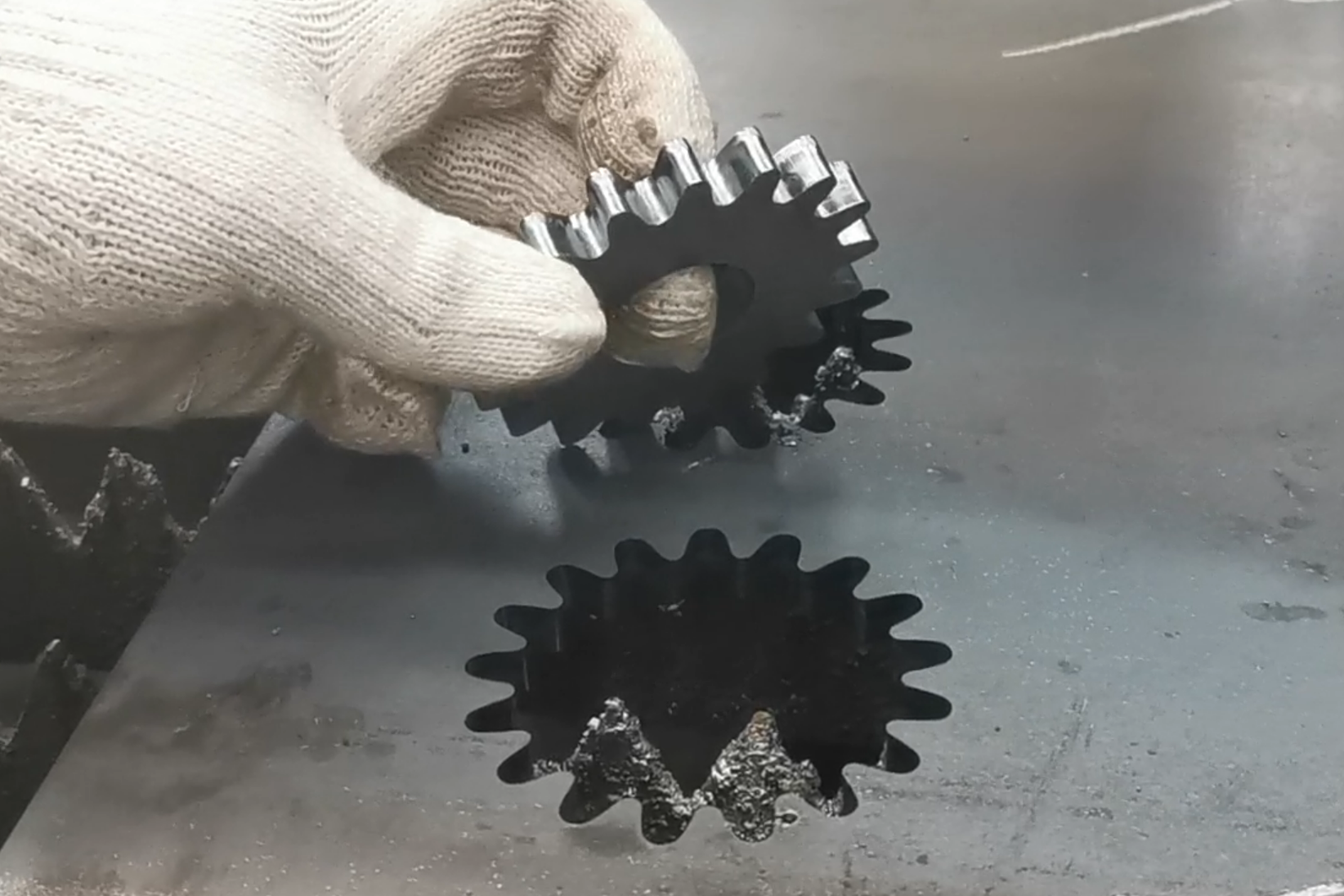

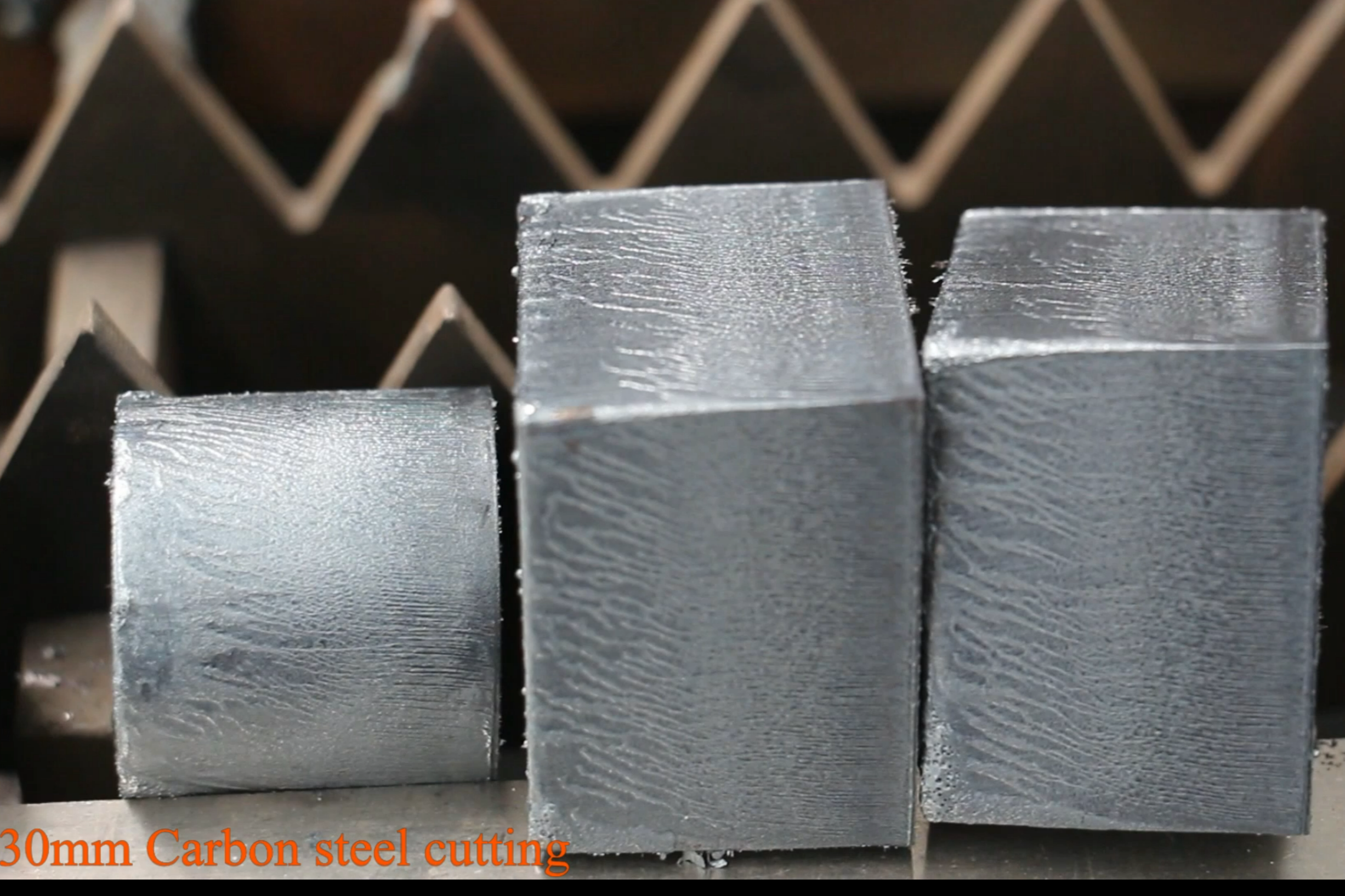

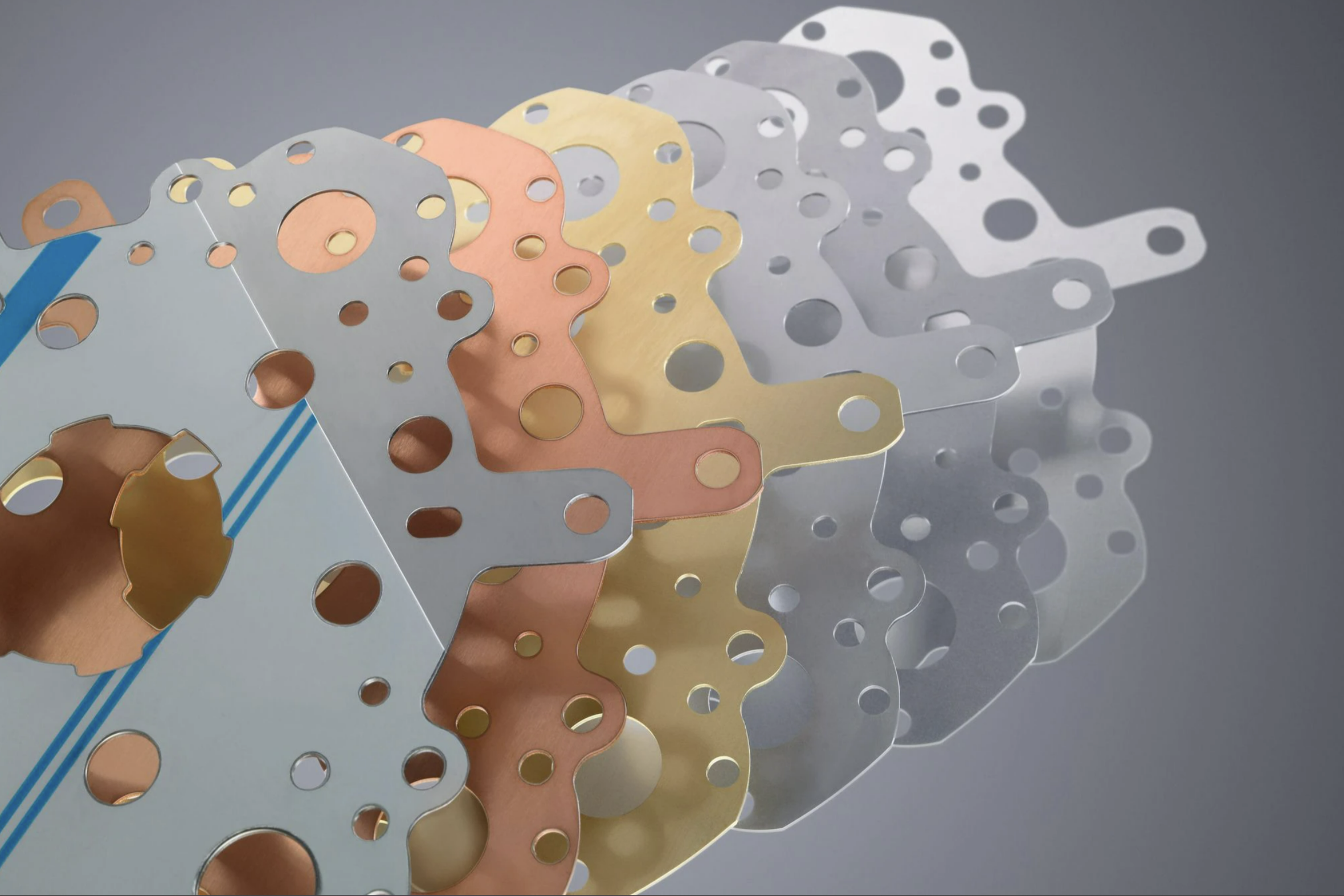

Laser Cutting Sample

.png)